MEMS Gas Analyzer

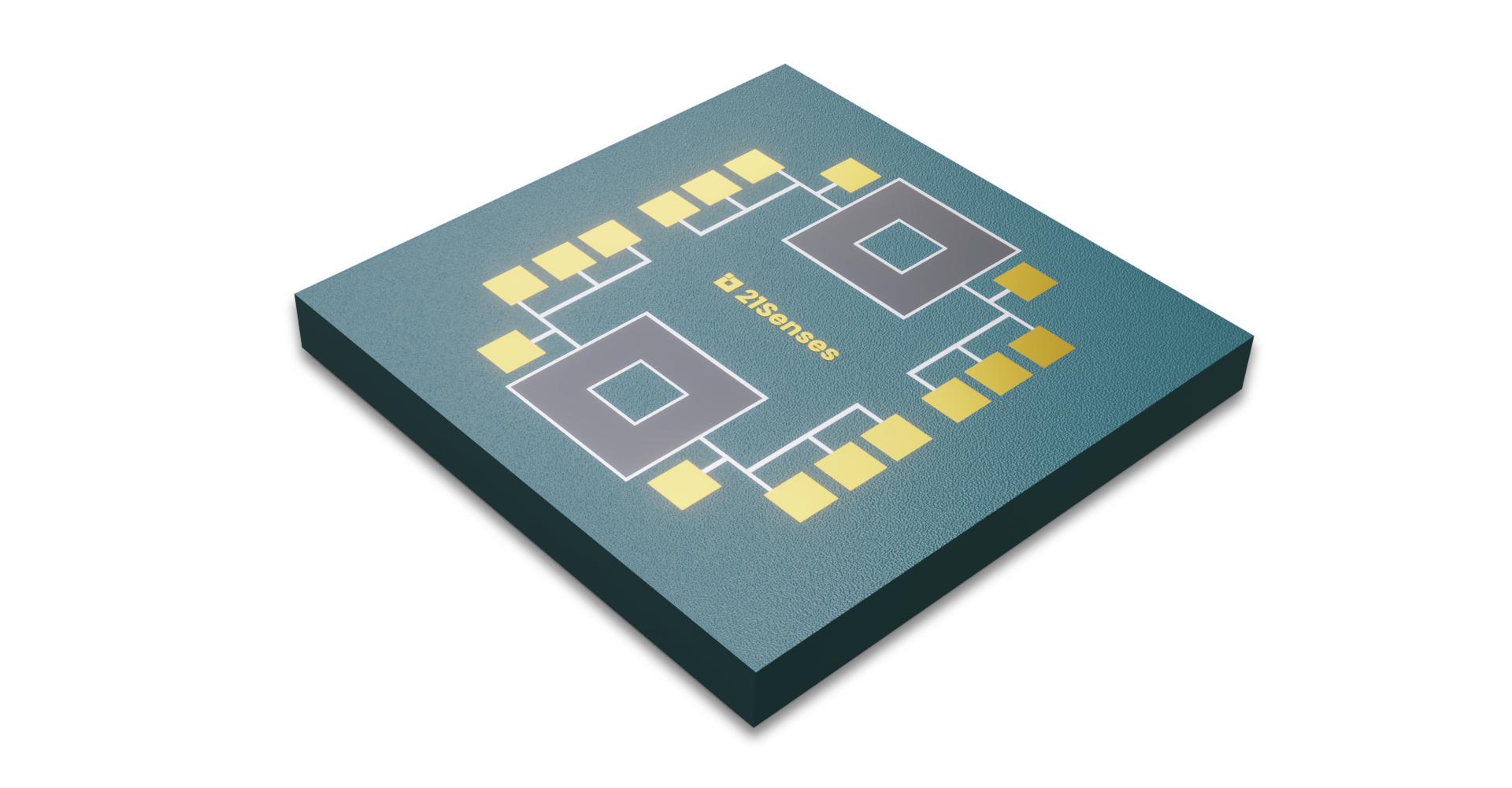

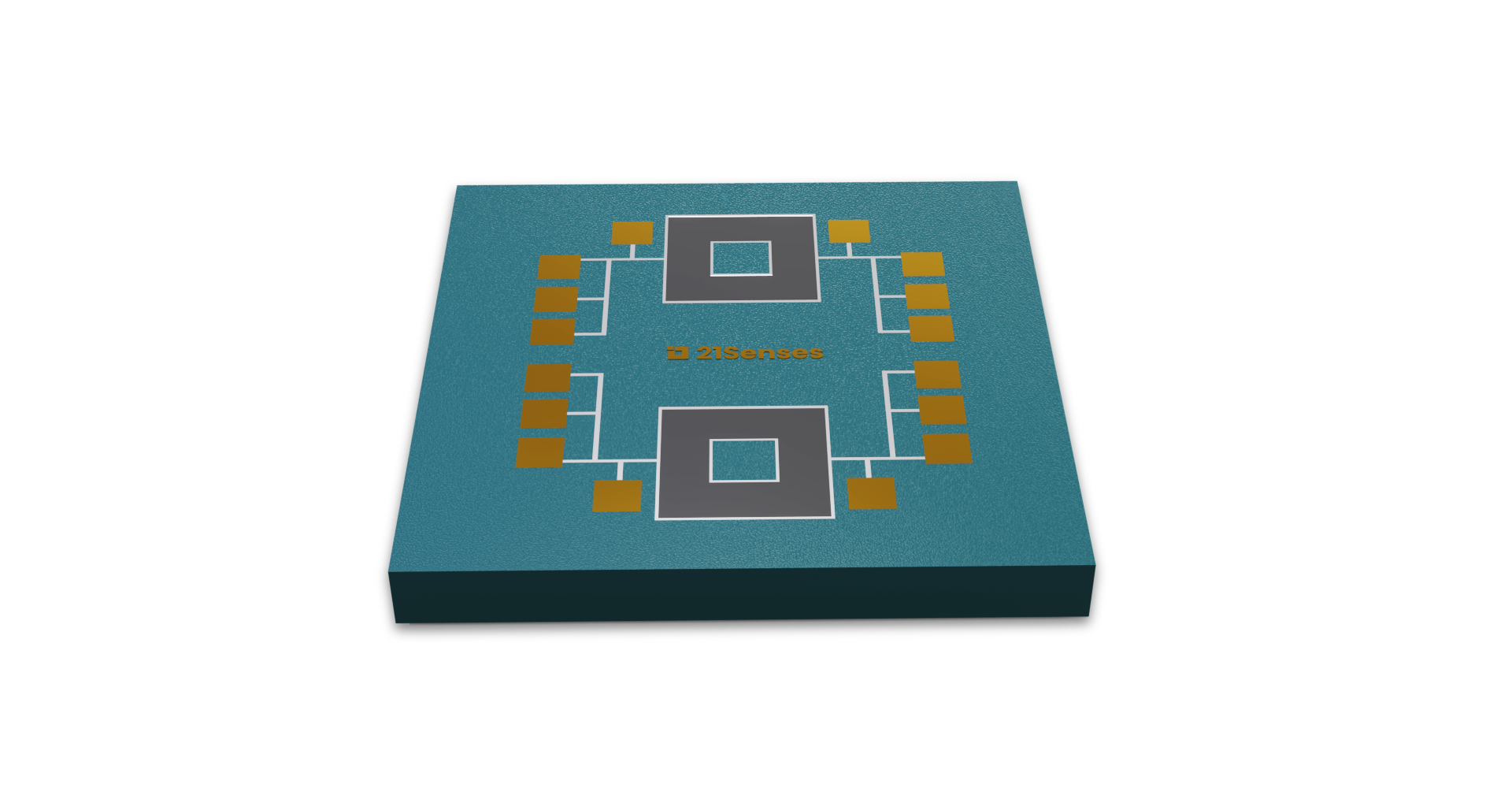

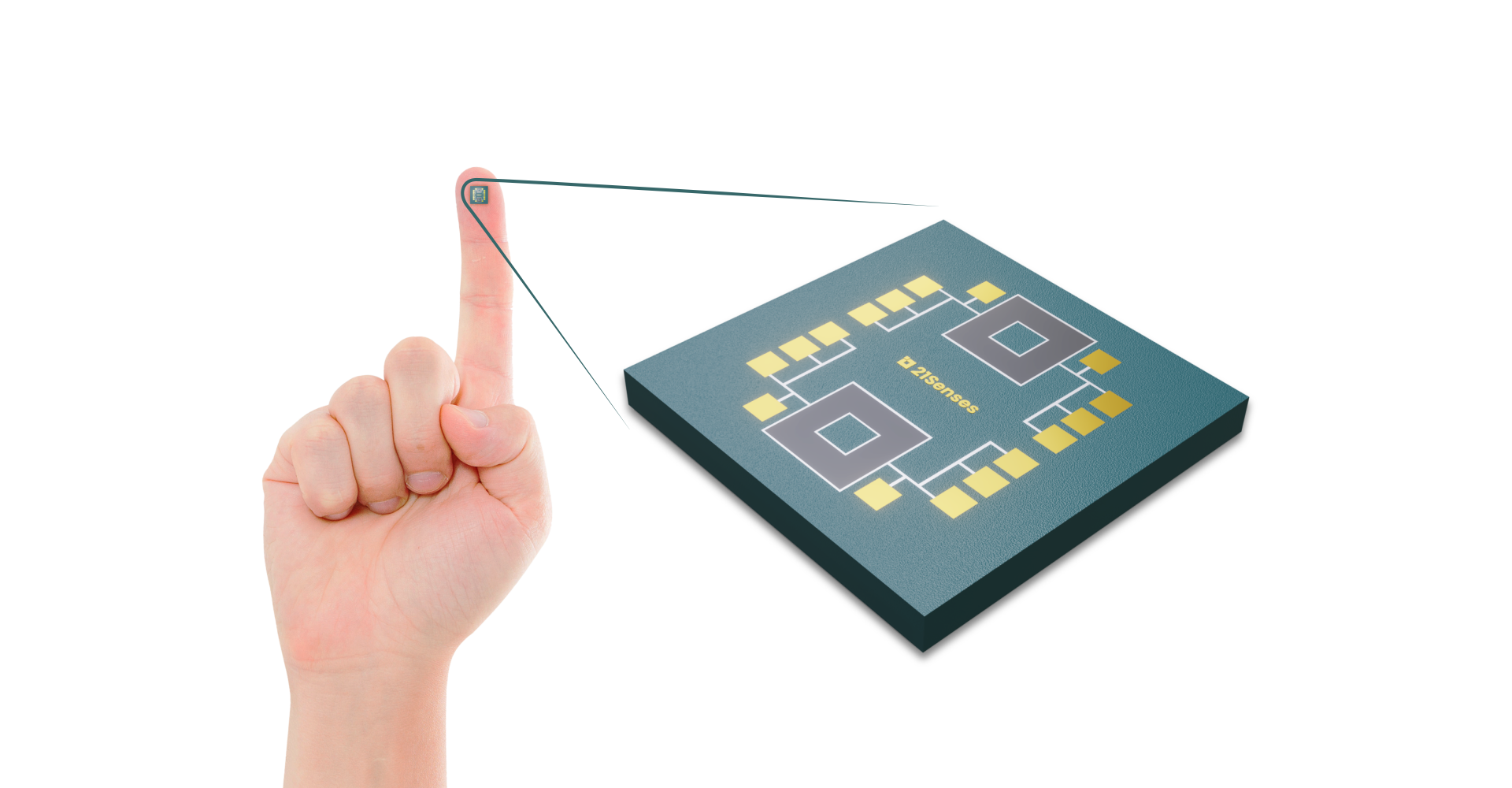

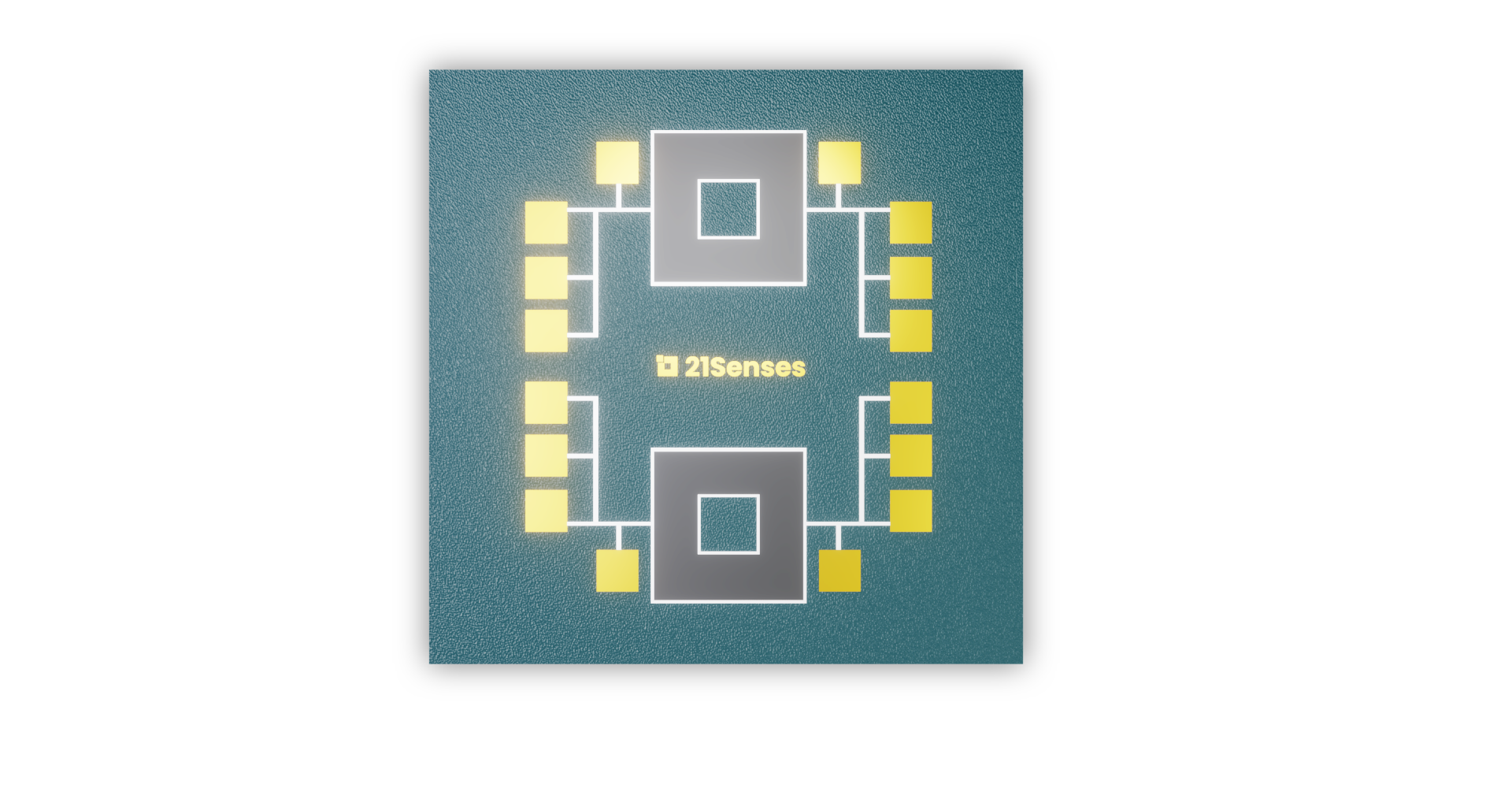

The PlatfoMEMS Omni-Gas Chip is a breakthrough technology that detects a wide range of gases in complex applications. Each chip has a pair of ultra-sensitive sensors that self-compensate for temperature and flow conditions and use smart algorithms for intelligent selective sensing. You can deploy our high-resolution sensors across target areas for sensitive, intelligent gas detection. Our simplistic design, small form factor, affordable price point, and wireless mesh deployment enhance safety coverage. Discover advanced gas detection with PlatfoMEMS Omni-Gas Chip.

With ultra-compact size and sensing range options from 0% - 100% for target gases, you'll have the flexibility to detect specific gas at any concentration. Our response time is unbeatable, with T20 to T90 in a few hundred milliseconds, so you can react quickly to any environmental changes or take corrective action. Additionally, our sensors won't sustain any damage at any level of overexposure and work in a temperature range between -40℃ to 300℃.

Product Features:

Game changing advantages of this technology stack are as follows:

- Ultra Compact Size: PClatfoMEMS Omni-Gas Chip measures 3mm x 3mm x 0.5mm with near analytical capabilities.

- Fast Response Time: Ultra-fast response and recovery time T20 to T80 in <1 sec.

- High stability of output: Capability to accurately resolve small changes in gas concentration on a real-time basis.

- Customized Packaging: Can be packaged as per the use case requirements and conditions of use.

- High-Temperature Deployment: Sensor heads can be deployed into high-temperature zones from -40℃ to 300℃, with ongoing work to push the limit up to 600℃-700℃.Electronics can be placed in the ambient environment.

- Smart algorithms: Tune the sensor platform to different target gases in binary mixtures.

- Integration Options for OEMS: Ideal for integration into high-temperature environments, critical equipment, white goods, energy storage systems, and other smart applications.

- Communication: equipped with industry-standard analog and digital communication protocols.

- Chip on Board applications can be supported with development tools.

Configuration Options:

1. Real-Time In-Situ or Sample Line Analysis – Any binary mixture with gases having distinct thermal conductivity, for process analysis and leak detection – Ready for POC Trials and Solution Development![SK1]

- Hydrogen Purity (40% to 99.99%)

- Alkaline, PEM, SOEC Electrolyser Raw H2 and Purified H2 real time analysis

- PEM, LT-SOFC, HT-SOFC Fuel Cell H2 feedstock real time analysis

- Hydrogen in Air (0% to 99.99%)

- Leak detection

- Exhaust line H2 analysis for incomplete combustion

- Hydrogen in Oxygen (0% to 99.99%)

- Electrolyser exhaust line H2 analysis for H2 / O2 chamber sealing insights

- Submarine Lead Acid battery health monitoring

- Hydrogen in Methane (0% to 99.99%)

- Hydrogen – Piped Natural Gas blend analysis and control for home fuel

- Hydrogen – CNG blend analysis for vehicular fuel

- Syngas real-time analysis

- Hydrogen (5%) Nitrogen (95%) Tracer Gas Leak Detection in Air Background

- Leak detection quality control in manufacturing industries including Automobile Components, Medical Devices, HVAC, Packaging and other.

- Helium in Air (0% to 99.99%)

- Leak detection quality control in manufacturing industries including Automobile Components, Medical Devices, HVAC, Packaging and other.

- Hydrogen in Carbon Dioxide (0% to 99.99%), Carbon Dioxide in Hydrogen (0% to 99.99%), Carbon Dioxide in Air (0% to 99.9%)

- Tri-Gas analysis of Hydrogen, Carbon Dioxide, and Air for Hydrogen Cooled Power Generator for Operation, Purging, and Maintenance Activities

- Hydrogen in Inert Vacuum (0% to 99%)

- Space applications to detect Hydrogen fuel leakage into vacuum layer.

- Syngas – Carbon Monoxide, Hydrogen, Carbon Dioxide and Methane – Breakup of 100% composition with the remainder as contaminants.

- Methane or Piped Natural Gas in Air (0% to 99.9%)

- Leak Detection for Pipelines, Storage Terminals, and Home End Point Installations.

- Measuring and analysing Greenhouse Gas Emissions

- LPG in Air (0% to 99.9%)

- Leak Detection in households to avoid catastrophic explosions

- Diborane in Hydrogen (0% to 10%)

- In-Situ analysis in Semiconductor Manufacturing Equipment

- Moisture in Inert (0 to 1,000 ppm)

- In-Situ analysis in Semiconductor Manufacturing Equipment

- Sulphur Hexafluoride (SF6) in Air (0% to 99.99%)

- Leak detection in SF6 filled circuit breakers and electrical switchgear

2. High Temperature In Line Sensing – Ready for POC Trials and Solution Development!

- Hydrogen in Exhaust Gas for Hydrogen ICE Engines (0% to 100%)

- Air to Fuel Ratio for CNG, H-CNG, H2 with Air/ Oxygen (0% to 100%)

- High-Temperature SOFCs Hydrogen Analysis (0% to 100%)

3. Qualitative Trend Analysis Based Predictive Intelligence – Coming Soon!

-

- Lithium-Ion Battery Safety – Hydrogen, Solvent Vapours, Carbon Monoxide, Carbon Dioxide (0 to 50,000 ppm)

- Transformer Health Monitoring – Hydrogen, Carbon Monoxide, Carbon Dioxide, Methane, Ethane, Ethylene, Acetylene and Moisture (Dissolved Phase 0 to 20,000 PPM)

Technology & Product Roadmap

Our team of passionate engineers is dedicated to developing cutting-edge technology that will take gas sensing to the next level. We’re expanding our technology stack to incorporate more sensing principles into a single die, allowing for parts per billion level sensing of toxic gases. We’re also developing a MEMS-based gas separation column to integrate with the chip, creating a near Gas Chromatography capability at your fingertips!

Use Cases:

The use cases are covered under the configuration section.